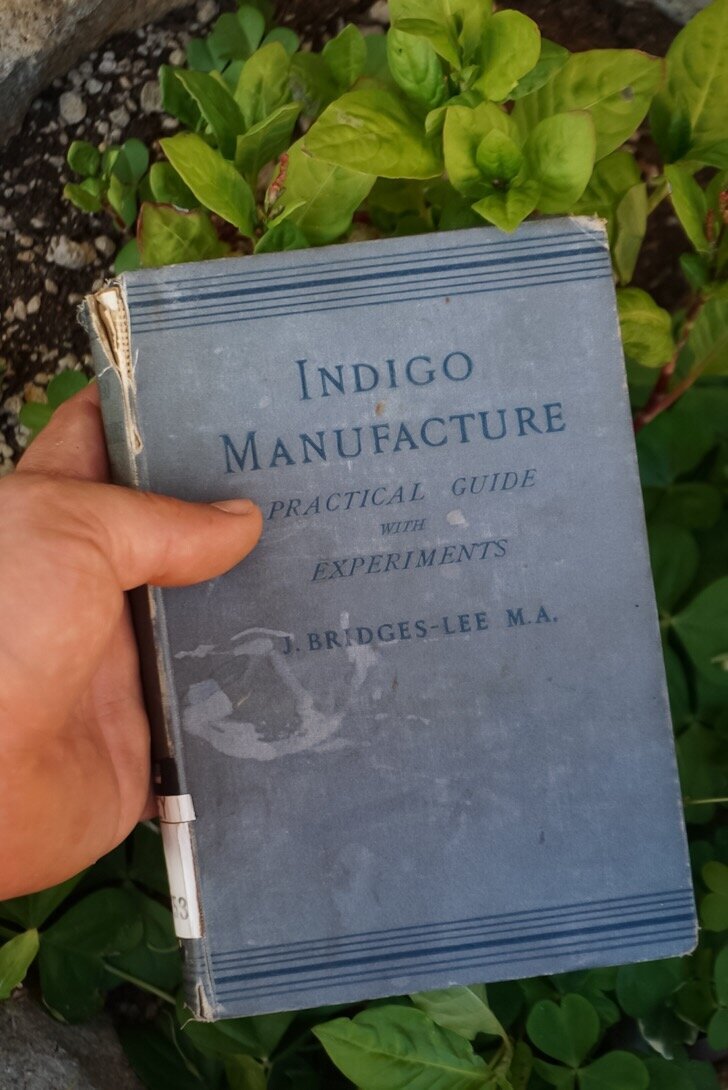

INDIGO MANUFACTURE

PRACTICAL GUIDE WITH EXPERIMENTS J. BRIDGES LEE M.A.

FOR MY COMPANIONS IN INDIGO EXTRACTION AROUND THE WORLD,

What follows is my transcription of a book initially published in 1892 on the processing of indigo pigment. This book was written by J. Bridges-Lee M.A. a British author regarding indigo production in India in that era. To the best of my understanding the book focuses on working with Indigfera tinctoria, or a related Indigofera genus plant. I found that it contained many practical pointers for indigo extraction. Though it was meant to support small production factories, much of the information is helpful and revelatory for individual growers. We now have modern conveniences (such as electricity and often a ready supply of water) at our disposal to aid with the processing, but the concepts around the plants and color extraction remain relevant.

This book came to my attention via the now closed American Textile History Museum. Upon their dissolution, copies of a number of textile manuals were gifted to the Marshfield School of Weaving in Vermont in 2017, where I teach in the summer time. I was able to handle and examine the book and found it to be full of helpful, reasoned information.

I’ll place a free download of the book here, if you’d prefer to have a .pdf, otherwise, please enjoy! I’m going through the trouble to transcribe it here because the scan did not do a perfect job with transferring the text to digital copy. With the fully transcribed version here, you’ll be able to search the volume reliably. I’m also adding in the chapter note titles into the text to allow for easier browsing.

This text was written by a British planter, operating in colonial India during the British occupation and the tone and vocabulary reflects as much. The information contained in the book is a combination of descriptions traditional practices as well as ideas toward promoting efficiency and quality of the finished indigo product. The publication of the book precedes the creation of synthetic indigo by less than a decade. I’ve found this dissertation helpful in adding some context to the environment and era (1890s Indigo Production in British Colonial Bengal) immediately following this publication.

My personal practice with using traditions, pigments and practices is gleaned from the work of artisans and people of craft the world over. I lay no claim to any tradition, but instead seek to share information that I find useful and insightful in as free a way as I am able. I hope that this information may help you deepen your craft and understanding.

I’ve now completed the transcribing of the text. It is all here, available for you to search through as you wish. In the coming seasons, I’ll be trying to construct some equivalent oxidation and filtration devices as the author patented with the publication of the book to aid in the processing of the pigment. As I develop methods and photographs, I’ll add them into the text below.

GRAHAM KEEGAN

LOS ANGELES :

2021.

___

INDIGO MANUFACTURE

PRACTICAL GUIDE WITH EXPERIMENTS

J. BRIDGES-LEE M.A.

INDIGO MANUFACTURE.

ON INDIGO MANUFACTURE:

A PRACTICAL AND THEORETICAL GUIDE TO

THE PRODUCTION OF THE DYE:

WITH NUMEROUS ILLUSTRATIVE EXPERIMENTS

BY

J. BRIDGES-LEE, M.A., F.G.S.

CALCUTTA :

THACKER, SPINK AND CO.

BOMBAY : THACKER AND CO., LIMITED.

LONDON: W. THACKER AND CO., 87, NEWGATE STREET

__

1892.

PREFACE.

_____

This monograph deals only with the subject of Indigo manufacture, and it is hoped that it may prove of real service to persons interested in Indigo — whether proprietors or planters.

Indigo planters in India live in isolated places, for the most part miles away from each other. They generally learn the details of their business by serving a kind of apprenticeship as assistants to older hands. The ordinary routine of practice is fairly simple and easily learnt, but the true theory of indigo manufacture is very little understood, and unnecessary losses are frequently incurred in consequence; and planters; have often been known to lose large sums of money through listening to the suggestions of people possessing a very little quasi-scientitic knowledge.

I believe that the contents of this monograph cannot not fail to be of use to the classes of persons for whom it has been written. I have, myself, made most extensive original experimental investigations in connection with the subject-matter of my monograph, and one distinctive feature of the work consists of descriptions of numerous simple experiments at the end of each chapter, to illustrate the principles enunciated in the body of the preceding chapter. These experiments are all of such a character that they can easily be repeated by any Indigo planter with the most ordinary appliances, and they should contribute materially to a better and more real understanding of the subject than could be acquired by mere enunciation of facts and theories.

J. BRIDGES LEE.

LAHORE, JANUARY, 1892.

CONTENTS.

_____

CHAPTER

I.—EXTRACTION OF THE SOLUBLE MATTERS FROM THE PLANT BY WATER

VARIOUS STEPS OR PROCESSES

CONDITIONS AFFECTING QUANTITY AND QUALITY

FERMENTATION THEORY FALLACIOUS

TRUE THEORY OF STEEPING VAT

IMPROVED METHOD OF EXTRACTION

HEATING AND MANAGEMENT OF THE VAT

TREATMENT OF THE PLANT DURING STEEPING

METHOD OF APPLYING PRESSURE

METHOD OF PACKING THE PLANT IN THE VAT

ORGANISATION OF TRANSPORT FROM FIELD TO VAT

DEEP VERSUS SHALLOW VATS

SECOND STEEPING WORTHLESS

EXPERIMENTS TO ILLUSTRATE CHAPTER I

II.—WATER

WATER SUPPLY

CLEAR SOFT FRESH WATER BEST FOR THE PURPOSE

ADVANTAGES OF A LABORATORY

METHODS OF TESTING AND ANALYSING WATER

FILTRATION OF WATER

SUBSIDENCE OF WATER TANKS

WELLS, AND THEIR USE AS FILTERS

BENEFITS OF AN OVERHEAD WATER TANK

PURIFYING WATER BY TREATING WITH CHEMICALS

EXPERIMENTS TO ILLUSTRATE CHAPTER II

III.—THE OXIDISING VAT

STRUCTURE, PLACING, AND ARRANGEMENT OF THE VATS

DESCRIPTION AND USES OF THE BEATING RANGE

PRACTICAL WORKING OF THE BEATING RANGE

DEALING WITH THE LIQUID AFTER BEATING

SUBSIDENCE AND DRAINAGE

IMPROVED METHOD OF OXIDATION

ALTERNATIVE METHODS

EXPERIMENTS TO ILLUSTRATE CHAPTER III.

IV.—LATER STAGES OF MANUFACTURE

BOILING: METHODS OF APPLYING HEAT

RUNNING FROM BOILER OVER TABLES

SOFT INDIGO: CAUSES AND PREVENTION

PRESSING THE CAKES

PRESSES FOR “MAL”

METHODS OF DRYING

IMPORTANCE OF AVOIDING DELAY IN MANUFACTURE

IMPROVED METHODS OF SEPARATION AND FILTRATION

ILLUSTRATIVE EXPERIMENTS TO CHAPTER IV.

INDIGO MANUFACTURE.

CHAPTER I.

EXTRACTION OF THE SOLUBLE MATTERS FROM THE PLANT BY WATER.

VARIOUS STEPS OR PROCESSES

The various steps or processes in indigo manufacture at an indigo factory may be grouped in natural sequence under three heads :—

(1) The treatment of the raw plant with the object of extracting from it the ingredients which at the next stage in manufacture will yield the indigo.

(2) The treatment of the product extracted from the plant for the purpose of obtaining from it a granular precipitate of indigo blue.

(3) The collection and subsequent treatment of the indigo blue precipitate, with the purpose of converting it into good, sound, dry merchantable cakes.

The first stage of manufacture is probably the most important, because upon the treatment of the plant itself will primarily and chiefly depend both the quantity and the quality of the dye afterwards obtainable

As might be expected from the large extent to which the plant is grown, and the high market value of the dye, a number of different persons have at various times devoted attention to the methods of manufacture, with a hope of being able to improve on the old primitive methods, and various mechanical arrangements have been devised from time to time, which have to a certain extent assisted or superseded manual labour, but in principle the methods by which indigo is obtained from the plant to-day are essentially the same as they have been since the days of our forefathers.

In principle these methods consist:—

(1) In the extraction of soluble matters from the plant by water.

(2) In precipitation of indigo blue from the aqueous infusion by the oxidising influence of the atmosphere.

(3) Draining off the mother liquor from which the indigo blue has precipitated, and in boiling afterwards with water, straining, compressing and drying the precipitated indigo.

In this chapter I shall treat only of the extraction of the soluble matters from the plant by water.

EXTRACTION OF SOLUBLE MATTERS BY WATER

The old-fashioned, time-honored method is now and has always been, to steep the raw fresh-cut plant in large vats, at the ordinary atmospheric temperature, i.e., no artificial means are used either to raise or to lower the temperature of the plant, the vats, or the water.

The common practice is first to pack the fresh-cut shrubs as closely as possible in the vat, then to spread layers of the plant horizontally, so as to make the uppermost level of the plant as nearly as possible horizontal, then to lay on the top of the plant a horizontal trellis-work of bamboos, then to compress the plant by pressure applied above the bamboo trellis-work, the pressure being exerted by means of various simple mechanical arrangements of levers or stout wooden beams; the beams pressing on the bamboo trellis-work are then pegged or otherwise fastened down to the level to which they have been depressed, and, lastly, water is allowed to flow into the vat, until the level of the water in the vat is a few inches at most above the uppermost level of the plant. After all this has been done, the whole vat is allowed to rest until the planter, relying on his personal experience, thinks the steeping has lasted long enough, when valves, communicating with the base of the vat, are opened, and the liquor is allowed to drain off. Ordinarily, the time during which the plant is allowed quietly to steep is from ten or twelve to sixteen hours or more.

Commonly the steeping commences in the afternoon of one day, and the liquor is drawn off some time in the following morning. As before said, the time of steeping is determined by the planter or his assistant in charge of the factory, but the time actually required for steeping is determined, in great part, by the state of the weather, hot or cold, wet or dry, the state of the plant when it was put into the vat, and the quality of the water. The planter, besides taking general note of these circumstances, will especially observe the changing condition of the uppermost surface of the liquor in the vat, and observation of the state of the surface of the vat, and of the colour of the first portions of liquor which flow off at the bottom, afford fairly satisfactory guides to enable a practical man with experience to decide when the whole liquor in the vat should be drawn off.

The above description, with occasional modifications, represents the ordinary practical treatment of the raw plant, and, so far as I am aware, no important improvements on the general methods above described have hitherto been introduced in practice.

Many persons have tried from time to time the effect of adding various chemical substances to the steeping vat, and some few persons have perhaps imagined that by such means they have improved either the quantity or the quality of the ultimate produce, but the general consensus of opinion among practical Planters of long standing would seem to be that all kids of doctoring stuff introduced into the steeping vat are useless, or worse than useless and there can, I think, be very little room to doubt but that this opinion is correct.

CONDITIONS AFFECTING QUANTITY AND QUALITY

So far as as the steeping vat is concerned the essential conditions for good produce are (a) good plant; (b) good water ; (c) correct steeping. By (a) good plant I mean plant of a good quality raised from the seed of plant known to be rich in indigo-dye producing material.

The plant should be in good condition, and clean and unbruised ; and the whole of the plant used for one steeping should have been cut at or about the same time, and be all in approximately the same condition as regards freshness ; otherwise it will certainly happen that the freshest plant will be under-steeped when the stale plant commences to be over-steeped.

It does not fall within the scope of this small treatise to discuss the conditions to be observed for rearing good plant ; we are only concerned in this place with a discussion of the means for obtaining the best possible results from the plant as delivered at the factory. At the same time, it is, of course, essential to bear in mind throughout that it is the plant which yields the indigo-forming material, and, except the plant contains a good supply of that material, you cannot hope to obtain a good supply of produce.

Whether indigo exists ready formed in the plant, as deoxidised or white indigo, or whether it is formed ultimately from indican or from other substances, there is no doubt but that the indigo-white or other indigo-forming substance or collection of substances extracted from the plant by water is formed in the living plant by vital processes appertaining to the plant itself. A maund of the plant, when cut, has within itself a certain quantity of material freely soluble in water, which is capable of yielding, on exposure to the air, a certain number of grains of indigo. You may, by defective manipulation, fail to extract a considerable proportion of that substance, or you may extract nearly the whole; but you cannot increase the total quantity of that substance which you had to start with in the fresh cut plant. When the vital processes by which indigo forming material was formed in the plant come to an end, the manufacture of the material by the plant ceases.

FERMENTATION THEORY FALLACIOUS.

Indigo, as the planter gets it in the oxidising vat, is a direct product of the oxidation of something soluble in water which existed in the living, growing plant, and is certainly not a product of subsequent fermentation.

This last-stated proposition it is important to insist upon, because there is a general, widespread belief among planters that the ultimate formation of indigo blue depends upon a process of fermentation as it is called, in the steeping vat, and this fallacious belief has served to divert people's attention from the true theory of the steeping vat, and so to prevent the discovery of more expeditious and more cleanly methods than those in common use. I have accordingly taken some pains to set out in detail at the end of this chapter a number of simple experiments to show that fermentation is not necessary for the production of indigo blue; and I trust that any planter who will take the trouble to repeat those experiments will be able to satisfy himself, not only that no sort of fermentation is necessary to produce good indigo, but that any amount of the so-called fermentation or putrefaction which there may be during the process of manufacture, causes positive injury to the indigo product by adulterating it with filth, and considerably impedes all the later stages of manufacture.

In truth, there is no special distinctive kind of fermentation for the indigo plant, so far as I have been able to discover by careful observation and very numerous oft-repeated experiments.

The indigo plant-like nearly every other kind of green plant will rot if left in water long enough, and while rotting it will give rise to all sorts of foul, offensive, stinking products of decomposition ; and, like other rotting plants. will give off foul smelling gases, but at no stage is there any specially distinctive kind of fermentation apart from progress on the road to decomposition and decay, i.e., there is no fermentation of a kind corresponding to the alcoholic, or acetic, or butyric fermentation.

In practice, of course, no one ever thinks of leaving the plant to soak in the steeping vat till it rots, but before the liquor is drawn off changes have commenced, or even sometimes progressed some distance on the road which leads to the development of those slimy products which cause so much trouble and annoyance when they appear in quantities at the later stages of the manufacture.

The general belief that there is a special fermentation process, and that the formation of the indigo is dependent upon this process, would seem to be based upon, the twofold observation — first, that the liquid in the steeping vat does froth up while the steeping is going on, in the same sort of way that a beer vat would froth when fermenting ; and secondly, experience has told the planters that the best time to chaw off the liquor is after the escape of gas bubbles has commenced to slacken, and the frothy head has begun to subside. Planters have also learnt by experience long ago that if they were to draw off the liquor before the frothy head had formed they would get exceedingly little indigo.

These facts and observations have afforded a plausible sort of basis for the prevalent theory, but the theory is not sound, and the observed facts are capable of another explanation, and are all consistent with what I believe to be the true theory of the vat, while there are many experimental facts which distinctly negative and are inconsistent with the fermentation theory. The true theory of the steeping vat is exceedingly simple, and is this :—

TRUE THEORY OF STEEPING VAT

The leaves of the indigo plant, which contain by far the largest proportion of the indigo-forming materials, are covered with multitudinous tiny hairs very close together. These hairs entangle air in their interspaces and when the plant is first flooded with water the leaves do not get wetted, except at their edges or where by chance they may have been roughly handled or bruised and every leaf will have over nearly the whole of its surface a protecting film of air which serves effectually for a time to hold off the liquid. The stems and branches and cut surfaces of the plant are not similarly protected, and they are wetted immediately or almost immediately, by the circumambient water, which they absorb in moderate quantities, as the water has less density than the plant-juices. This absorption of water causes the plants to swell, and a certain small amount of movement among the immersed plants, and greatly increased pressure in every direction between adjacent parts of plants, the liquid absorbed by the stems and branches travelling, of course, also to the leaves and causing them to swell also. These slight internal movements of the solid and liquid contents of the vat, and especially the pressure and occasional sliding motion of leaves in contact, will result in driving out some of the air in the shape of bubbles, so that a mild kind of bubbling will commence early in the steeping process, but the actions already described will not by themselves suffice to lay bare the greater part of the leaf surfaces to the action of the water.

This result will only be achieved when the action of small living organisms comes into play on a large scale, as it will after some hours. No matter how fresh the plant when first packed in the vat, or how fresh and clear and sweet the water when first let-on, the liquid after a variable number of hours will be found to teem with microscopic animalcules, in a state of the liveliest activity, and these myriads of minute organisms will rapidly lay bare all the leaf surfaces within their reach, by attacking and eating the hairs and by keeping up a state of violent molecular activity throughout the whole mass of the liquid, so that the previously entangled air will now rapidly escape in bubbles of gas, which will force their way to the surface and make the froth-head appearance so well known.

When the frothy head begins to subside, then it may be know that nearly all the leaves have come in contact with the surrounding fluid. The indigo forming substance is freely soluble in water, and the leaves are so thin that contact with the water on both sides for an exceedingly short space of time suffices to extract all their soluble juices, and it is time to draw off the liquor. Nothing Can be gained by waiting longer. Some small proportion of the leaves are probably still not wetted, but most will be, and, meanwhile, the oxygen of the air will have already commenced to precipitate appreciable quantities of indigo blue near the surface of the vat, all of which will be lost to the planter, as it will not find its way down through the plant to the oxidizing vat. Also the animacules, before referred to, will go on multiplying at a prodigiously rapid pace, and their living and dead bodies and their ejections and the debris which they have succeeded in detaching from the surfaces of the plants, will all contribute to make the liquid more or less milky or slimy, and to spoil the ultimate quality of the indigo, and impede the subsequent operations of settling and pressing and drying.

In accordance with the above-stated theory of the steeping vat, it will be seen that the planter’s first need in dealing with the raw plant is, after he has obtained good water to wet it, to proceed to get it wetted. The ordinary method of steeping is a lengthy process at best and is open to the objection above pointed out.

IMPROVED METHOD OF EXTRACTION

Obviously, if my theory is sound, it would be well, if possible, to dispense with the animalcules altogether, and also to avoid disintegrating the plant ; and if the operation of extraction could be quickly performed there would be a great saving from every point of view, and a purer product. These results I have achieved by the simplest process of applying heat to the bottom of the vat after it has been packed with plant and flooded with cold water as usual. I begin to heat the vat below immediately the vat is charged, and in my experiments I have found from one hour to one hour and a half sufficient time for the process of extraction, prior to draining off the liquor to the oxidizing vat.

HEATING AND MANAGEMENT OF THE VAT

An ordinary fire under proper control, or steam pipes, or hot water pipes will do to heat the vats.

I do not ordinarily raise the mean temperature of the vat contents above 150° F. as I find that by the time that temperature is reached all, or nearly all, the air bubbles have been cleared out, and subsequent inspection of the plant has shown that it was all thoroughly moistened. Also I have found that the produce of indigotin is larger wit this method of extraction than with the ordinary cold steeping method.

The effect of heating the vat from below is, of course, to cause convection currents, which sweep past and over the surfaces of the leaves, and so help to sweep away the air. Also the heat expands the air, and so aids its escape ; also, I think it probable that the warm liquid acting on the hairs softens them, and so enables the air to be more easily swept away.

My method certainly does not engender fermentation of the vat contents before the liquid is drawn off, and it yields a clear, bright fluid, free from all suggestion of muddiness or sliminess.

This method of extraction, as my readers will observe, is new.

TREATMENT OF THE PLANT DURING STEEPING

PRESSURE ON PLANT IN STEEPING VAT.

While treating of the steeping vat, and before going on to consider the subject of water supply, to which the next chapter will be devoted, it may be as well to point out that the old-fashioned method of compressing the plant in the vat is clumsy and unscientific, and results in loss of indigo, besides occasionally causing loss to the planter in other ways.

Indigo plant before steeping is of less density than water and it is obviously necessary to use artificial means to keep it down, otherwise a large quantity of the plant would be floated up above the water surface, and the idea of pressing and fixing it down very naturally suggested itself to the earliest pioneers in indigo manufacture.

Also if the plant is pressed down very tight a relatively smaller volume of water is required for a given weight of plant than if the plant were loosely packed and lightly held down ‘ and, accordingly, with close packing and tight pressure, it may be expected, as will, in fact, be the case, that the liquor to be dealt with in the oxidising vat will contain a larger percentage of the indigo-producing material than in the case of loosely packed and slightly compressed plant.

On the other hand, if plant is too tightly compressed, there may be increased obstacles to the water getting at all the parts of the plant in the vat it may be difficult for the air bubbles to find escape towards the surface.

These advantages and corresponding disadvantages of pressure would apply to any kind of pressure, however applied, but the existing method of fixing down the plant to a definite horizontal level, by a rigid arrangement of levers and pegs, is open to much more serious objections, which have only to be stated to be understood.

In the first place, the pressure originally applied to the freshly packed plant, bears no sort of ratio to the pressure which will be exerted upon the plant after the water is let on and during the subsequent stages of steeping.

Plant which has been only moderately compressed on the outset may, during the process of steeping, and while the stems are swelling with absorbed water, develop a pressure so great as even to break the beams or rend the solid masonry to which these are connected. Such excessive pressure at this stage serves no useful purpose whatever, and may occasion damage to the planters.

Also when most of the entangled air has escaped from the vat, and after all or most of the leaves have got wetted, and their soluble contents dissolved out, the downward pressure on the plant will be so slight as sometimes to be almost nil.

The plant by this time will have lost much of its rigidity, and the density of the wetted leaves is actually slightly greater that that of water, so that a well-soaked sprig of the plant will sink and not float in pure water. Hence it will happen that when the time for draining off the liquor arrives there will be but little downward pressure on the plant except the weight of the plant itself, which will alone come into operation as the water level in the vat sinks during the process of draining off.

METHOD OF APPLYING PRESSURE

IMPROVED METHOD OF APPLYING PRESSURE

These various objections can all be got over by the very simple expedient of using a dead weight above the bamboo trellis-work instead of making any attempt to fix it down to a definite level.

The dead weight may be made just as heavy or just as light as may be required, and will act uniformly through all stages in the steeping, and will serve to add slightly to the yield by assisting the last portions of liquor to drain off from the plant when the vat is drawn.

The kind of dead weight which I prefer to employ consists of a number of solid bars of iron with square cross section.

Each of these bars should be about a foot less in length than the breadth of the vat, so that it can be conveniently placed upon the bamboo trellis-work without danger of tilting against, and so injuring, the sides of the vat.

Each one of these bars should be notched at regular intervals with rectangular notches, extending just half way through the thickness of the bar.

To pack the weight, all that is then necessary is first to lay a series of these bars upon the bamboo trellis work, taking care that they be all at equal distances apart and parallel, the distances corresponding to the intervals between the rectangular notches.

When one layer has thus been laid with all the notches uppermost, a second layer is laid at right angles to the first layer, with all the notches downwards, so as to fit exactly into the notches of the bars below. In this way a rectangular trellis-work of iron is formed, the parts of which cannot slide upon each other ‘ and the pressure will always be a known quantity, and can be duly proportioned to the amount of plant in the vat.

In practice it will probably be found convenient to use bars of such weight, that either one man at each end or two men at each end can easily sling them into position, with the aid of loops of ropes under the ends.

PRESSURE IN STEEPING VAT

To facilitate the laying of the iron bars at the proper distances apart and parallel to each other, I use a rectangular frame of wood to fit the vat, and provided with notches and grooves to receive the ends of the bars one by one as they are laid. With this arrangement, the loading on of the weight can be completed easily and quickly, and very few men and no machinery will be required. The pressure actually required to produce the best practical results is not nearly so great as might be imagined by anyone who has not gone into the matter experimentally. Strictly speaking if your plant has been well and closely packed, comparatively very little pressure per square inch will be required to keep it down below the level of the water, provided that the initial flooding of the water level has been raised to a height of some few inches above the uppermost level of the plant. The bouyancy of the plant is at no time anything remarkable, from start to finish. The chief cause of the bouyancy at first is the entangled air, which, as previously explained, forms a film over the surface of every leaf ; and if warmth is applied to the vat, the expansion of this air by heat will tend to increase the bouyancy, until such time as the air has detached itself from the plant and gone off as bubbles. This process of detachment of air-bubbles is a process which goes on during the whole period of the steeping, and the remaining plaint gets less and less bouyant the more air has escaped, till at last it has little or no bouyancy left. To overcome the mere bouyancy not very enormous pressure is therefore required, but besides bouyancy proper, there is the other pressure previously referred to, which is of quite a different nature, and which is generally amply sufficient under existing old-fashioned arrangements to make the beams crack, and sometimes even to break materials which would not yield except to a force of many tons.

This kind of pressure is due to a swelling out of the substance of the plant itself as it absorbs liquid, and as is the case with the other molecular forces, the pressure originated from this cause may be prodigiously great, but it will operate only through very short distances.

This kind of pressure si the same kind of pressure as is exerted by roots which have worked their way into cracks in masonry, and which finally, as they expand in growing, rend open the masonry.

To attempt to counteract by artificial mechanical means the force of the expansion of the plant as it swells with absorbed moisture, is to attempt something which it is hopeless to think of accomplishing on a large scale, and if you could succeed you would have gained nothing practically. In practice, the height to which the upper level of the plant will be raised in consequence of the swelling out of the plant structures will be very small, less indeed, with indigo than with many other common plants, and in the deepest vats ordinary use the rise of level from this cause will never exceed a few inches.

A fixed dead weight, such as I would use, can yield to this pressure, and rise a few inches withoug any harm being done, but it will not yield to any tendency for the plant to float and from the nature of th earrangement proposed, any dead weight will always exert the same pressure on teh plant from the start to finish.

This use of dead weight, as described above, in place of mechanical pressure, such as has commonly been employed at factories has been patented under the Inventions and Designs Act of 1888.

METHOD OF PACKING THE PLANT IN THE VAT

PACKING OF PLANT IN STEEPING VAT

The next matter we will consider is the method of packing the plant in the vat. Some planters attach much and some comparatively little importance to this.

The matter is not really of any vital importance ; it is best to pack the plant upright , as far as is conveniently possible, using horizontal layers only to fill up inequalities in the upper surface so as to make the upper surface as nearly horizontal as possible.

The advantages of an upright packing are, first and chiefly, that gas bubbles can escape much more freely from vertically packed plant than from plant horizontally packed, so that, as before explained, the plant will more quickly get wetted. Also as convection currents in liquids mostly play up and down, and as the leaves for the most part will have an approximate average vertical direction when the plant is vertically arranged, the leaves will be more easily and more quickly swept clear of air, and the internal circulation of the fluid contents of the vat will be less impeded than if the plant were horizontal.

Further, when the plant swells from absorption of moisture, the swelling will be mostly in thickness, and the stems will not elongate to any considerable extent.

With vertical packing the swelling of the plant will not, therefore, tend to any considerable extent to raise the plant out of the liquid.

ORGANISATION OF TRANSPORT FROM FIELD TO VAT

TRANSPORT FROM FIELD TO VAT

Probably the best of all possible methods of pack ing is to first make up all the plant into bundles of convenient sizes, every bundle to consist of one-half of the plant standing erect, and the other half upside down. By this means a close packing can be obtained, while preserving the general vertical arrangements of the stems and leaves, and with good management it ought to be possible altogether, or nearly altogether, to dispense with a horizontal layer at the top .

That horizontal layer when it is close packed, as it usually is immediately upon the leaf tops of the vertical plant and then firmly compressed from above, is apt to oppose a considerable obstacle to the escape of gases from beneath. I would suggest that when the fresh plant is first cut in the fields it should be immediately tied in bundles of convenient standard size, and weight, and it should be the business of some responsible servant on the spot to see these bundles made up immediately as the plant is cut.

These bundles should then be packed carefully on the carts, and on arrival of these carts at the factory should at once be transferred, without opening, to the vats in process of being filled. The man in charge at the field should have a book in which to enter the total number of bundles cut and despatched, and the man in charge of the packing of the vat should have another book in which to check off the packing. By following the course suggested the planter will be enabled to obtain fairly accurate information concerning the produce per acre of the different fields under cultivation He will also know, approximately without the trouble of having any weighments at the factory, how many maunds of plant can be packed in each vat, and he will be able to estimate roughly the efficiency of the work of cutting, carting, and packing in the vats, all matters of some importance from a pecuniary point of view ; and, besides, if some little pains be taken in securing that the bundles are built up uniformly in the first instance, there should be little or no difficulty in packing the vat uniformly, and entirely with the plant stems pointing up and down, so that a dense layer of compressed leafy structure at the top will no longer be required to render the upper surface approximately horizontal.

Probably the best plan to construct the bundles will be to have all plant as it is cut transported immediately by coolies to some one place in the field, where there should be a weighing machine, similar in general construction to the machinery used for weighing luggage at railway stations, but instead of a small platform there should be a larger flat platform to the machine, the length of the platform to correspond with the length of the bundles to be made.

The bundles should be then constructed by first laying transversely on the platform a piece of common rope of the proper length, to tie the completed bundles ; and then a man, whose special duty it should be to make up the bundles, should as rapidly as possible lay on the plant lengthwise in successive handfuls, having the cut ends of the stems pointing towards opposite end of the platform; and he should see that the two ends of the bundles reach but do not to any extent overlap, the ends. So soon, then, counterbalance the weight agreed to be taken as the standard unit, he should tie the rope round the bundle , and it should be at once transferred to a cart standing near. It is, perhaps, needless to observe that the space around the machine should be all kept as clean and free from dust and dirt as possible. Probably, in most cases a liberal spreading of clean straw will be found to be a convenient bed on which to lay fresh-cut plant before it is weighed and loaded.

SYSTEM OF RECORDS BY TICKETS

Every cart when it is loaded should be ticketed, the ticket to bear a serial number to show the number of bundles it contains, the weight, the field, and the time of loading, and when it starts for the factory; the time of despatch should also be noted on the ticket, and a man at the factory should note the time when the cart arrives there.

Every effort should be made to ensure that the weighment, loading, and despatch shall go on regularly , and keep pace as nearly as possible with the cutting of the plant in the field.

The order of the despatch of the carts from the field to the factory should follow the order in which they have been packed, and when the carts reach the factory they should there be drawn up in order of loading, so that the first cart loaded shall be the first unloaded, and so on, the bundles being in all cases, when this is possible, transferred direct from the carts to the vat, and when the vat has been charged, it should also be ticketed by transfer of the cart tickets of those carts which have been unloaded into the vat, and also by a separate ticket to set out the time when loading commenced, the time when finished, the total number of bundles of plant, or, what is the same, the total weight of plant in the vat, and the time the water is let on, and, ultimately, the time it is drawn off, together with any special notes, which the planter in charge may think it useful or interesting to make.

When the steeping vats are drained off, the whole block of tickets should be transferred to the oxidising vats, which should have also their own special tickets, and so on through all stages of manufacture, up to the ultimate stage of packing and despatch of the indigo chests, when the bundles of tickets may be transferred to pigeon-holes in the factory office, and kept as part of the office records for as long as is thought desirable. The vats themselves should bear consecutive numbers, and should be brought into use in regular consecutive order, no fully charged vat being kept waiting for water till the next is filled; and directly a vat is flooded with water, the process of warming up the vat should be started, and the particulars of the time, temperature, &c., carefully noted on the vat ticket. For convenience sake, the tickets representing all stages of manufacture — from the field to the packing — case may be strung together on wire, the tickets being all provided with small brass eyelets, the uppermost ticket at any time representing the facts of the stage of the manufacture then in progress, and the tickets below representing all the past stages in regular backward order. Also, it may be convenient to represent the different stages, so as to facilitate easy after reference.

The system of regular, continuous, uninterrupted working, and of the preparation and of the preservation of continuous contemporaneous records in the shape of a series of tickets, will, if put into operation, be found to assist the planter very considerably in checking and supervising all stages of the manufacture. To some readers, the system proposed may appear to present practical difficulties ; but most of these can be got over by a little care and determination. The time consumed in making the necessary entries on the tickets will be very little indeed; and the advantages of having an efficient check system of records are so great that it is well worth while to make a determined effort to get such a system into regular working order. One of the greatest difficulties of factory administration is the obtaining and organisation of sufficient and efficient transport during the “mahai ” season; but if this department is not well organised, and bullock cart drivers and others are allowed to bring in plant at all sorts of times in an irregular, haphazard sort of way, and to deposit it more or less promiscuously in sheds, from which it is removed after irregular intervals of time to the vats, the planter will certainly be a loser in more ways than one.

For really efficient economical working, every arrangement about the factory should be co-ordinated to every other. The plant should be loaded and brought in as soon as it is cut, it should be packed in the vats and steeped as soon as it is brought in, the liquor should be drawn as soon as it is ready for drawing; it should be submitted to the oxidising process as soon as it is drawn, and so on to the end. If you cut plant in excess of what you can carry away at once, you suffer waste of material. If, when plant reaches the factory, you have no vat ready to put it in, you again suffer waste of material and labour. If you keep one vat waiting for another to be filled, you lose time, and therefore money, in the shape of a share of the daily wages of the people employed, and your plant suffers and falls off in indigo yielding capacity, and so on everywhere through every stage of manufacture, a haphazard or irregular system of working means loss on all hands as compared with a regularly co-ordinated system.

Hereafter I shall show how, with the aid of a properly co-ordinated system of working, and some improved methods at various stages, the manufacturing capabilities of any given factory may be increased at least fourfold, and often to a much greater extent, without any considerably increased tax on the factory resources, except in the matter of transport. As most existing factories are now worked, it not unfrequently happens that a period of four or five days, and occasionally even more, may elapse from the time when carts first reach the factory with plant to the time when the finished indigo product is ready for transfer to the drying house; whereas with really efficient arrangements the maximum period of time, from the arrival of the plant to the conclusion of the cake cutting, should never exceed twenty-four hours, or may even be reduced to twelve hours, with no injury, but rather benefit to the quality and quantity of the finished product in relation to the quantity of plant used.

DEEP VERSUS SHALLOW VATS

DEPTH OF THE VATS—SURFACE OXIDATION

Another matter for consideration in connection with the steeping is : what should be the depth of the vat in relation to its other dimensions? All steeping vats which I have ever seen are square, but in my opinion they are all too shallow in proportion to their other dimensions. Probably planters have found, or at least the persons who were mainly instrumental in settling the present common form of the vat, must have thought they found some practical advantages in the kind of vat adopted, and I have been informed recently by a planter that some of the most recently constructed vats in Tirhoot and Bengal have been built even more shallow than the vats hitherto used, under a belief that shallow vats yield larger produce. If this is really a prevalent belief among planters in these days, I am at present at a loss for want of statistical facts to ascertain upon what materials exactly that belief is based. Theory seems to indicate with sufficient clearness that the steeping vat should expose a very small surface to the atmosphere, and the oxidising vats a large surface.

Experiments in thin glass vessels, where the progress of operations can be watched, point clearly to the conclusion that there is always some waste of indigo from oxidation at the surface of the steeping vat before the steeping process is fully completed, and the larger the exposed upper surface the greater the waste from this cause.

The extraction of the plant by water will proceed quite satisfactorily in a bottle fitted with a cork, through which a fine glass tube, or a quill, of tooth pick size, is passed so as to allow of the escape of gases from inside the bottle, but to allow no quantity of air to flow into the bottle. Altogether it can be proved in many different ways that free access of atmospheric air is not necessary to promote the progress of the steeping process, and it can also be demonstrated that if, on the other hand, air is blown into the steeping vat, a quantity of blue indigo will be precipitated, which will adhere to the plant when the liquor is drawn off, and so result in the loss of produce.

DEEP AND SHALLOW VATS DISCUSSION

With my method of warming up the vat contents by artificial heat, I have not the least doubt but that the deep vats will yield better results than shallow vats in proportion to the plant used.

It is possible that where shallow vats are now used some benefit may be derived from the heating action of the sun's rays, when they reach the vat either in the evening or after sunrise.

It is a matter of general observation among planters that the steeping process is more rapidly completed when the vats are warmed by the sun's rays than when the whole process is completed in the shade.

Also the animalcules, of which I have previously spoken, are fond of light and warmth, and they will develop in greatest numbers near the surface, where, with the common method of packing and pressing the densest layers of plants are to be found.

These causes may hasten the steeping process, and the total volume of produce may be increased by the bodies of myriads of the animalcules and fragments of disintegrated plant-tissue, while with a deep vat there would under the ordinary system be comparative stagnation in the lower parts of the vat, and the leaves, which chance to be packed at a considerable depth below the surface, might still be unwetted, even after the upper layers were completely extracted.

Hence it is possible to understand how and why shallow vats may have come into favour, if they have Besides, shallow vats are more easy to pack and to empty than deep vats. They require less strength and depth of masonry. Shallow layers of plant are more easy to compress than deep layers, and will develop a smaller total of upward pressure when the plant expands, and so endanger to a less extent the compressing structure and the masonry; and a lower head of water will suffice to flood them, and therefore less pumping power will be required to be used. All these considerations are so many points in favour of the use of shallow vats under the present common every-day method of working; and if, besides, they yield as much or more produce without any considerable falling off in quality, there would seem to be sufficiently strong reasons for preferring to use them.

On the other hand, shallow vats do certainly entail the immediate loss of a certain quantity of good indigo. Anyone watching the surface of the vat just before the vat is about to be drawn, and during the drawing-off process, will see that this is a certain fact; and if the upper layers of plant are afterwards picked up by hand and examined, they will be found to have a film of insoluble blue indigo adhering to them. The loss of indigo from this cause can be shown to be directly proportioned to the extent of surface exposed to the air. Here we are face to face with a perfectly certain loss, which is, with equal certainty, due only to the action of the air over the exposed surface; and this loss can be directly avoided in proportion as the extent of exposed surface is limited. Hence, other things being equal, a vat exposing small surface to the air is to be preferred. So long as a planter depends mainly upon the action of animal organisms developed in stagnant water to lay bare his plant to the solvent action of water, a larger surface may, perhaps, be on the whole desirable; but if the plant can be got at by the water under the influence of convection currents, caused by heat applied near the bottom of the vat, then the necessity for depending upon animal organisms disappears, and the more the surface exposed to the atmosphere can be contracted the better.

WITH IMPROVED METHODS DEEP VATS BEST.

Hence, with my method of heating the steeping vat, a deep vat is better than a shallow vat, from this cause. Also, if a dead weight is used as pressure in the way before pointed out, all danger from over violent upward pressure disappears. Also convection currents will operate more effectually in a deep than a shallow vat. Also, with the method of packing above advised, the whole internal structure of the vat contents will be fairly uniform, and though there will still be somewhat closer texture of plant immediately below the weight than elsewhere in the vat, the plant will not be so densely matted in that region as to oppose any very serious obstacle to the free escape of gas bubbles, and it will be found that so far from the plant rising out of the liquor as the steeping goes on, that the weight will, after a short time, sink down to a lower level in the vat, carrying the plant before it, and when the liquor comes to be drained off, the weight will subside, and thus materially assist in squeezing out part of the liquor which might other wise remain adherent to the plant and be lost, together with its contained indigo, when the plant was cleared out of the vat.

The objections on account of the necessity of having to raise the plant bundles to a higher level, and of having to pump water to a greater height, are of small moment, as the extra cost from these causes will be infinitesimal; and the increased difficulty of packing and unloading a deep vat will be minimised by using firmly-tied bundles of uniform dimensions, which can be packed, like sacks of grain, side by side, layer above layer (always on end), and unpacked by hooking them up by their belly bands.

Accordingly, in every factory where it is proposed to use my method of warming up the vat after it is charged, I would suggest the advisability of raising the side walls of the vats to two or three times their present height, so as to convert a 1,000 cubic feet vat into a vat of 2,000 or 3,000 cubic feet.

When this is done it will be necessary to look to the strength of the existing masonry, because every extra foot of water in vertical height will add an extra pressure on the structures below of nearly half a pound to the square inch.

This consideration will, among others, impose limits upon the depth which can be given to large vats, and convenience of packing and unpacking has also to be considered, so that about three times the ordinary depth will probably be found to be the deepest vat which it will be convenient to use.

Under the system above advocated, by which every vat is flooded directly it has been packed and weighted, and heated directly it has been flooded, it will seldom happen that more than one, or at most two vats, will be in process of being heated up at the same time.

The appliances for artificial heating should be so regulated with reference to the capacity of the vats that the temperature of each vat can at will be raised from 80° F. or 85° F. (the ordinary average temperature of the tank-water) to a temperature of from 150° to 160°, in the space of from one hour to one hour and a half.

It will be best always to commence the heating up gradually, then more rapidly, and when the temperature of the bath at one or two feet below the surface stands at 150°, it may be allowed to rest for about ten minutes preparatory to drawing off, as to give time for suspended dust particles to settle on the plant.

So soon as the vat has been drawn, and sufficient time allowed for all the liquor to drain off which will drain off, the weight may be immediately taken off, then the bamboo framework, then the plant bundles may be taken out and transported to some convenient place near by, where they can be opened out and left to dry, the fragments of rope being kept to be used over and over again, until they grow too rotten to bear the weight of a bundle of plant.

SECOND STEEPING WORTHLESS

SECOND STEEPING UNPROFITABLE

There is no use in attempting to get a second crop of produce from the same lot of plant by a second wetting. The yield would be so excessively small as not to afford any sort of adequate compensation for the loss of time and power which the second steeping would entail. Practically you would get next to nothing. This many planters have learnt by practical experience to be the case, though most people I have talked to on the subject have not been able to understand why a fair second crop of indigo could not be obtained, and until I had embarked upon my somewhat elaborate investigations, I thought, as I believe many planters still think, that the plant must even yet contain a large quantity of indigo after the first brew of liquor was drawn off.

Now, however, I am convinced that this is not the case. The plant will, of course, be wet after the first brew has been drawn off, and the liquor with which it is wetted, as well as the liquid which permeates it in least as rich in that substance as the liquor which has just been drawn off. Of these facts there can be no reasonable doubt; indeed, the liquid in and immedi ately in contact with the plant might be supposed to be at least fractionally richer in dye-making material; but the total quantity of this liquor remaining with the plant bears such a very small ratio to the quantity drawn off, that, even if it were twice or three times as rich in dye stuff, which it probably is not, and even if it were possible to collect it all, the quantity would still not be worth recovering at the expense of having to fill up the vat again with water, and of having to oxidise it out from that water.

The indigo plant is a thoroughly non-succulent, non-spongy sort of plant.

The actual density of the plant, as before stated, is not very much less than that of water, and the leaves after soaking have a density slightly greater than that of water, but the structure of the plant is such that, to flood a small quantity of it, very many times its weight of water are required, no matter how closely it may be packed; and, when this is ultimately drawn off, the quantity left in or adherent to the plant forms only a very small fraction of the whole quantity.

But the indigo in even this very small residue of liquor cannot be abstracted by a second washing, be cause, as the first lot of liquor drained off, air followed it down, and, coming in contact with the films covering the surfaces of all the leaves and stems, the air will almost immediately have oxidised and rendered insoluble the minute quantities of indigo in those films. This little indigo, therefore, and the indigo which had been precipitated at or near the surface of the vat from the liquid there exposed to air, will be lost, and it is useless to think of recovering it by a second washing. The loss due to adherent films will be lessened to some extent by the use of a dead weight, as before explained, and the loss from surface oxidation may be minimised by limiting the surface area with reference to the total volume of the vat. For the rest, the liquid which is drawn off should, if the plant has been properly steeped, carry with it to the oxidising vat nearly all the indigo-forming constituents of the plant which has been steeped. After all parts of the plant have been exposed to the solvent action of water for a very short time, the water will have exerted its full solvent action on the plant; and, if longer steeping produces more copious quantity, it can only do so at the expense of quality. As a rule, short steeping by the old process gave purest colour and small quantity; long steeping, large quantity and bad colour. If you only steep the plant long enough, you will at last succeed in getting a plentiful filthy produce of almost a black colour, consisting of organic matter mixed with indigo; but the total quantity of indigotin which can be extracted from this produce of over-steeped plant will not exceed the quantity which could have been obtained from plant steeped for the correct time.

This concludes all that it seems to be necessary to say now about the first stage of manufacture, except as regards water supply, which will be treated of in the next chapter; but, before passing on, I would again warn my readers not to look for possible improvements in genuine produce as a result of doctoring the vat with chemicals. Some chemicals which have been proposed from time to time have been demonstrably only adulterants of the indigo; others have been added with reference to fanciful theories about imaginary fermentations which were supposed to evolve the indigo. So far as I know, the only chemicals which have ever been found to be of the slightest real service in the steeping vat have been chemicals whose ordinary effect in the laboratory is to arrest oxidation, as sugar, for example. When such chemicals are used, the period of steeping may be prolonged, but they also retard the later stages of manufacture; and are more harmful than useful to the planter who uses them, and by far the best plan to check oxidation in the steeping vat is to restrict the surface area of the vat.

EXPERIMENTS TO ILLUSTRATE CHAPTER I.

THEORY OF STEEPING VAT.

(1)

Take a sprig of fresh indigo plant, hold it by the stem, and plunge the whole into a bath-tub full of water; hold it there for half a minute or minute, then with draw it.

You will observe that the leaf surfaces have not been wetted by the water, and water drops on the leaves will run off in globules, like water off a duck's back.

(2)

Pack inside a peg-glass, or, better, a large glass water-jug (the larger and depper the better, if quite clear and transparent), some fine shoots and leaves of indigo plant; then lay a moderate weight of metal or clean stone on the tops of the leaves, then pour on water to cover the leaves and weight.

Observe how the immersed leaves all have a silvery appearance on their surfaces from the films of air which separate the leaf surfaces from the surrounding water.

Observe how long a time will elapse, if the glass be left to stand at rest in one place on a shelf or table, before the silvery-sheen appearance will disappear, and the leaves acquire that apparent bright green colour which will indicate that they are at last wetted, and that the air has ceased to separate the water and leaf.

Note the escape of bubbles from the leaf surfaces through the liquid. Note the formation of a film of blue indigo on the upper surface of the liquid at a later stage in the steeping. Observe the gradual development of a cloudy appearance in the upper parts of the liquid and the gradual penetration of a (1) bluish, (2) greenish, (3) yellowish milkiness downwards from the surface towards the clear yellow liquid below. Draw off with a pipette a drop of the cloudy fluid from near the top, and examine it under a microscope. Compare this with a drop drawn by another pipette from near the bottom.

(3)

Take a freshly gathered leaf and examine one of the leaflets under a microscope, both by reflected and by transmitted light, taking care not to handle the leaflet to be examined. Observe the hairs and their distribution over both surfaces of the leaf, and especially over the lower surface. Observe, also, the distribution of the stomata.

(4)

Take a handful of freshly gathered shoots and leaves and mash them up quickly with a pestle and mortar, adding a little water to make a thin paste. Strain this thin green paste through a fine handkerchief, and beat up the strained liquor with a fork in a soup plate. Observe that indigo will be oxidised out of the juice.

Note the absence of any symptoms of fermentation. Note the short time in which indigo blue begins to appear. The process of bruising the leaves in the mortar and moistening and straining need not occupy more than a minute or two. There will thus be no time for fermentation, as there are also no symptoms of fermentation, but the strained liquor will contain indigo-forming material; and, if this strained liquor be then rapidly filtered through filter paper under pressure, it will be found that ordinary blue granular indigo will separate out from the clear filtrate on oxidation, the time required for oxidation being about the usual time required for oxidising indigo, according to the method of oxidation employed.

Observe, also, how very little time is required for the indigo-forming substance to be dissolved out from the leaf mash by the water when the two are brought into intimate contact through the agency of a pestle and mortar.

(5)

Take a large test-tube or boiling-tube of thin glass, fill it three-quarters full of freshly gathered indigo leaves, and pour in water till the liquid rises above the level of the leaves in the tube.

Observe, as in the experiments 1 and 2, that the leaves are not wetted by the cold water, as evidenced by the sheen at their surfaces.

Proceed to warm the tube at the bottom over a spirit lamp; note, during the process of warming, how bubbles of gas escape, and gradually the leaves get wetted all over, as evidenced by the change of appearance (or, as you can satisfy yourself by repeating the experiment and taking out the leaves when this change of appearance is first observed). Note that, by the time the temperature of the tube contents approaches boiling point, even though this should be within two or three minutes only of the commencement of the heating, all or nearly all the leaves will be wetted. Pour off the clear liquor then, immediately, into a saucer, and beat it with a fork, when you will find that it will afford a good yield of very pure indigo.

Note how clear the liquor is when decanted, with a complete absence of milkiness (i.e., if you have not used dirty or dusty leaves).

Note specially the exceeding short space of time in which the indigo-forming substances can be abstracted from the plant in this experiment.

Observe the absence of fermentation. Satisfy yourself that the time consumed in the process of extraction is only the time necessary to bring the liquid into effectual contact with the plant for a minute or two, and satisfy yourself by reading, or by experiments on bodies which are known really to ferment, that true fermentation is a slow process requiring time, and not in any known instance a process which can be completed in a minute or two.

Repeat the experiments in various forms with test-tubes and flasks, and satisfy yourself that most of the air bubbles which rise to the surface during the warming arise from the surfaces of the previously unwetted leaves, and that, if the heating be not pushed to the boiling temperature of water, few, if any, bubbles will rise after the leaves are seen to be completely wetted.

(Note, ordinary cold water always contains a certain quantity of dissolved gas, such as air, carbonic acid gas, &c., these gases the water parts with on heating, whether there be any plant in the water or not, but this quantity is in common water not great, and should not suffice to mislead in your observations. You can get over to a great extent this possible source of confusion in your experiment by first boiling the plain water in the tube to expel dissolved gases, then let the tube with its contained water stand perfectly still till it has cooled down to the temperature of the atmosphere, then drop into the tube a freshly gathered compound pinnate leaf of indigo plant which has not been handled except at the base of the petiole (leaf stalk). As this will not sink unless weighted, a small piece of copper wire may be twisted round or tied on to the base of the petiole to sink the leaf, which will then stand with all its leaflets erect in the tube. Now warm the bottom of the tube over your spirit-lamp, and observe how the individual leaflets get cleared of their adherent films of air, and how, if you will cease to apply heat after the whole surface of all the leaflets is wet, there will be no further escape of bubbles from the leaves. This experiment should be performed in a room by lamp light, or in diffused daylight, because in strong sunlight a distinct class of chemical operations come into play under the combined influence of sunlight and chlorophyl (the green colouring matter of leaves), and these give rise to a slow evolution of gas bubbles; but this reaction is not fermentation, and is common to indigo leaves and to all green leaves of all or nearly all plants.)

Repeat the experiment again with a number of leaves, warming up the tube till all the plant is observed to be wet. Note, again, how the bubbling falls off as most of the leaves are wetted. Continue warming intermittently for a few minutes, until it is fairly certain that none of the leaves which are obscured from sight are still unwetted; and now, instead of at once pouring off the liquor, stand the tube upright and let it rest in a place where you can carefully observe it while it is cooling. You can then see that there is no regular continuing escape of bubbles, as there would certainly be if any process of fermentation were going on of such a character as to develop gases during the fermentation.

When the tube and its contents have cooled down to the atmospheric temperature, pour off the fluid contents into a saucer, and oxidise by beating with a fork. You will get indigo as before, in proportion to the quantity of plant leaf used, and the quality will be of the very best.

Before pouring off the liquor, note the film of oxidised indigo which has made its appearance at the surface of the liquor in the tube which has stood some time, and note that there has been no visible precipitation of blue indigo anywhere but at the surface exposed to the air.

These experiments under heads four and five should abundantly suffice to satisfy you that no process of fermentation is necessary for the production of indigo blue. I hope they will satisfy you that the fermentation theory of the steeping vat is quite untenable, and, further, these experiments, in conjunction with those which have gone before, all go to support my theory of the vat as put forward in this book, now, I believe, for the first time.

(6)

Dry some indigo leaves by spreading them out in the sun. When these leaves are quite dry, pound them into a fine powder in a mortar. Then pour tepid water on this powder, stirring them well together to secure that the whole of the powder shall be wetted as quickly as possible. As soon as it is all thoroughly mixed into a paste, strain through a fine cambric handkerchief. The fluid which comes through will, on oxidation, yield a fair crop of indigo.

In this case, of course, the plant hairs could not operate to entangle any air films to protect the plant. The pounded plant could be easily reached in all its parts by the water; solution of the contents out of the solid powder, will take a little longer than solution out of a previously moist mass, but it will be very quick, and there is nothing to indicate that any fermentation takes place.

In this case, if fermentation were to take place at all, the only time there could be fermentation would be while the leaves were being dried. In reality, there is nothing to show that there has been any fermentation during the process of drying; but, if this experiment were to stand alone, it might be fairly said that the plant may have fermented to a certain extent while drying. In various printed articles and books treating of indigo manufacture, it has, I believe, been stated, with reference to the Madras method of manufacture from dried plant, that the plant undergoes some kind of fermentation in drying.

I would point to the absence of any satisfactory evidence in favour of fermentation theory; and it will be seen at once that the results of this experiment are altogether consistent with my theory — that it is only necessary to secure access of water to the plant to enable the water to dissolve out the substance already there existing, which will, on oxidation, yield indigo blue.

The pounded dry plant is the common wasma of Upper India. It spoils rapidly, if it is allowed to get damp, when exposed to the air. The reason, of course, is obvious. Before the leaves were pounded, and after they commenced to be dried, the unbroken epidermis of the leaf formed a protective coating for the inner contents of the leaves, which prevented access of air to those contents; but, when the dried leaves have been pounded up, air and moisture can alike penetrate everywhere.

Moisture brings the indigo-forming substance into solution, and air oxidises and causes blue indigo to deposit on the moist particles of the powder. Hence moist wasma, which is bright bluish green at first, when good, turns nearly black after it has been exposed for a time to the air. It may be observed here that the indigo obtained from wasma, or from bruised plant, or even from dried plant which has not been intentionally bruised, will ordinarily be inferior in point of colour to indigo obtained from clear infusions of the fresh plant, the reason being that it will generally be more contaminated with chlorophyl and other vegetable matter. Chlorophyl is green at first when fresh, but on oxidation or exposure to light changes to shades of yellow and brown, which tints, mixed with indigo, tend to produce shades approaching to black.

These experiments are not, of course, quoted to show that equally good quality indigo can be obtained by all these methods — the one main principle which all these experiments go to demonstrate is that the indigo-forming substance, whatever it is, exists in the plant ready formed, and whenever water comes in contact with it, it will dissolve it out of the plant; and the experiments serve to explain why the ordinary steeping process, as practised in Bengal and Tirhoot, is so lengthy, and to indicate how the steeping process may be shortened.

It is interesting also to reflect how that, if the leaves of the indigo plant were not protected as they are, then any substance having the properties of the indigo-forming substance in the plant could scarcely be expected to be found therein after even a very moderate downpour of rain. Hence from à priori consideration it might have been expected that the leaves would be provided with some kind of protective arrangement, such as they do in fact possess, and that arrangement, like so many other arrangements in Nature, is beautifully automatic. The leaves have the greatest resisting power for water just at those times when an approaching rainfall is most probable, i.e., when the hygrometric state of the atmosphere stands at its highest, and, as the leaves dry up in a dry atmosphere, their resisting power becomes progressively less and less, until at last, when the leaf has been thoroughly dried, there is but very little resisting power left. These facts can be observed and experimentally illustrated, and are interesting, but we cannot spare time and space to go into them in full detail here; but it must be remembered that before you can get the indigo out of your plant, you have to overcome a very beautiful natural arrangement for protecting the leaves of the plant against the too close approach of water.

(7)

With reference to the remarks last above made and the importance attached to plant being all approximately of equal freshness in any given vat, you should, day during the rainy season, walk into an indigo field while rain is falling, and observe how effectively the leaves throw off all the raindrops which strike them, and, when the rain is over, cut a few of the freshest-looking sprigs and carry them quickly home. Try some of these fresh sprigs in your bath tub or in a jug, and note how mere immersion, or even immersion accompanied with a fair amount of internal agitation, will quite fail to wet the plant. You may move the plant up and down and backwards and forwards some scores of times before the leaves will get wetted.

Now take a fresh leaflet and compress it firmly between your thumb and finger, or lay it on the palm of your hand and rub the leaf surface with your finger, and re-immerse in water, and note how much more easily these leaves are wetted.

Now, take a sprig of stale plant, if you have any at hand-some plant, that is, which has been gathered a long time before — or take a piece of what is technically called burnt plant, and test that similarly by immersion or movement under water, and note how it is less difficult to wet.

Now, take a small lot of your very freshest and best leaf and pack it lightly in a peg-glass, and a corresponding lot of stale or burnt leaf in another peg-glass, and pour water from the same jug or gharra upon both lots at the same time, and put them aside to steep quietly under similar conditions. Then, at intervals of every few hours, draw off by pipettes corresponding small quantities of liquor from each glass, and compare the progress made in the steeping.

Also observe, through the walls of the glasses, the appearance of the plant and liquor inside; and, finally, allow both glasses to remain charged and to stand in the same places until the plant passes to the stage of being decidedly over-steeped in each, and note when this occurs in each case.

CHAPTER II.

WATER .

CLEAR SOFT FRESH WATER BEST FOR THE PURPOSE

In Chapter I. it has been shown how that the really essential requisites for the manufacture of good indigo are, in the first instance, good plant and good water.

Without good plant or good water it is useless to hope that you can make good indigo ; and, having given these essential requisites, the process of manufacture consists, in the first instance, in bringing the plant and water together under such circumstances that the water can really get at the plant.

If this can be satisfactorily effected, then the water will dissolve the indigo-forming substance out of the plant, and the next stage in manufacture will consist in getting the blue indigo precipitated out of the water solution, and all subsequent stages resolve themselves into mechanical arrangements for accumulating and cleaning and drying and working up the indigo into convenient blocks to be sent to market.

It is, therefore, evident that when it is proposed to erect a new factory, the site for the factory should be so chosen that it may occupy the most convenient position possible with reference to the lands on which indigo plant is grown, or about to be grown, and also with special reference to the abundance and quality of the water supply which can be made available for factory use.

When the site has once been decided upon and the factory built, satisfactory transport arrangements should be organised for getting in the plant with as little delay, as much regularity, and as little cost as is possible, and similarly the whole water supply system should be so arranged that there may be a never failing supply of good water when it is required for use.

The details of the water supply arrangement will vary greatly with the circumstances and situation of the factory, and can only be settled by careful consideration of those details on the spot, but there are certain considerations of general application which can with advantage be treated of here.

In the first instance, it can be affirmed generally that for the indigo planter's purposes soft water is good water as contradistinguished from hard water.

The indigo plant forms no exception to the general rule that vegetable infusions are best made with soft water.

If it were possible always to command a sufficient supply of clear, fresh rain water, this would be the best water supply possible for indigo manufacturing purposes; but, of course, this is not possible, and ordinarily the best practical source of water supply is from a running stream, especially from a stream which is fed mainly by the rainfall in neighbouring hills or by melting snow or ice.

Spring water is commonly hard water, and the water of a running stream may be hard if that stream is mainly fed from springs. Also the water of a running stream may become hard when it passes over certain kinds of rock, or receives drainage water from a highly calcareous soil.

Hence streams vary very much in quality for indigo-making purposes, and while some few streams may afford a steady supply of remarkably good water, others differ very widely among themselves, and some afford water of very different degrees of goodness and badness at different seasons and in different years.

ARRANGEMENTS FOR TESTING WATER SUPPLY

A prudent man, before deciding to erect a factory on any given site, would give very careful attention, not only to the quantity and regularity of the water supply, but also to the quality of the water, and would have copious specimens of the water analysed by the most reliable and experienced analytical chemists, if he could not effect satisfactory analysis for himself; but there are many factories which have been erected without any such preliminary careful investigation, and some of those factories have had for many years a regular supply of bad water, which has placed them at a disadvantage as regards other factories more fortunately or more judiciously placed.

Others, again, though these are very few indeed, have started with good water supply years ago, but the quality has deteriorated since, and there are some where the quality of the water supply varies in different years.